I can honestly say that Hatton is one of the

most beautiful places I’ve ever been to.

Simply stunning. The weather was

patchy but we did have some periods of sunshine where I could take better pictures

– but even the best pics can’t even come close to conveying just how beautiful

this place is. The rolling hills,

covered in rows and rows of verdant green tea bushes, interspersed with vibrant

colored flowers and bushes, plus huge magnolia (I think) trees with a riot of

bright orange-red flowers bursting from their upper branches.

|

| View from our bungalow - a bit overcast but still gorgeous |

Also – Bed Tea. How

have I managed to live my entire life without being aware of the existence of

Bed Tea?? What is Bed Tea, I hear you

cry? Well, it’s when the Butler comes

and wakes you up with a huge lovely steaming hot pot of tea, served directly in

your room. Some people might just call

that “tea” or “room service” but not here.

Oh no. That would be doing a

disservice to the glorious golden liquid deliciousness lovingly poured by one

of the bungalow boys. Alas, I fear

ManpanionTM has already attached himself too firmly to this concept and now

every morning I’ll be awoken by him pointing at his mouth and squawking “BED

TEA!!! WHERE’S MY BED TEA?!”

Anyway, enough of that.

Our first day was a pretty lazy day, with the only thing on the

itinerary the Tea Experience – a tour of the Dilmah tea factory, that’s nestled up in

the hills. Breakfast was served out on

the back verandah, overlooking the lake – despite the rain (again), the views

were still pretty breathtaking. From our

vantage point, you could see one of the other Tea Trails bungalow, Castlereagh,

across the lake. To get to it, you

walked down through the sloping grounds to the jetty, where a little putt-putt

boat was moored, ready to ferry us across the lake later that morning for our

tea tour. We enjoyed a very yummy

English breakfast (thanks, Baby Chef) and afterwards, the chef came out to run

through the menu for lunch and dinner that day.

All terribly civilized!!

Anyway, enough of that.

Our first day was a pretty lazy day, with the only thing on the

itinerary the Tea Experience – a tour of the Dilmah tea factory, that’s nestled up in

the hills. Breakfast was served out on

the back verandah, overlooking the lake – despite the rain (again), the views

were still pretty breathtaking. From our

vantage point, you could see one of the other Tea Trails bungalow, Castlereagh,

across the lake. To get to it, you

walked down through the sloping grounds to the jetty, where a little putt-putt

boat was moored, ready to ferry us across the lake later that morning for our

tea tour. We enjoyed a very yummy

English breakfast (thanks, Baby Chef) and afterwards, the chef came out to run

through the menu for lunch and dinner that day.

All terribly civilized!!

|

| Outside of the Dilmah tea factory |

Just before 10am, we headed down to the jetty where a few others were already in the boat waiting, then we made the 10min crossing over to Castlereagh. We were loaded into a very tall mini-bus thing which then proceeded to bounce us up the hill for the next 10mins to get to the tea factory. On arriving there, we joined some additional people and were then introduced to Bernd, who was going to be our tour leaders.

A bit of history first about Dilmah tea, courtesy of Wikipedia:

Dilmah is a Sri Lankan brand of tea, sold internationally.[1] The company was founded in 1988 by Merrill J Fernando. The name Dilmah was chosen by combining the first names of Fernando's sons Dilhan and Malik. It is available in over 100 countries, including Estonia, the United Kingdom, Turkey, Lithuania, Pakistan, Poland, Russia, Hungary, Canada, Chile, South Africa, Australia, Indonesia, Japan, the United States and New Zealand. In 2009 it was considered that Dilmah was the sixth-largest tea brand in the world.[2]

|

| Tea factory, surrounded by beautiful gardens and tea bushes |

The Company's founder, Merril Fernando, was born in 1930 in the village of

Pallansena, near

Negombo. He moved to Colombo, where he became one of the Ceylonese tea tasters, training at

Mincing Lane, London. In 1974 Fernando bought his first few tea estates to try his hand at producing Sri Lankan tea, and in 1981 he founded Ceylon Tea Services Limited. In 1985, Merril Fernando convinced the Australian supermarket retailer

Coles to stock his brand of tea, Dilmah. He spoke to a Coles buyer about stocking his tea and eventually won him over. In 1988 a

Melbourne Coles store started stocking Dilmah on its shelves. It eventually spread to 35 other Coles stores in

Victoria and then

Woolworths started selling the product as well. Dilmah later exported the tea to New Zealand, where it is currently the top-selling brand,

[3] and also to

Europe and

North America. Today Australia makes up 10 percent of Dilmah's global annual retail sales.

[4] In September 2009 Ceylon Tea Services, Dilmah’s parent company, earned

US$5.2 million on US$19.7 million in revenue, which was up from profits of US$1.3 million, on US$18.6 million in revenue the year before.

[2]

|

| Our tea guide, Bernd |

Beyond all the dry numbers and statistics is actually a pretty cool company, one who was undoubtedly progressive in its time when it first started out. Despite pressure to expand to compete with multinational global brands, Dilmah is still a family-run business and was founded on real solid principles of environmental sustainability and respect for the environment. There is also a strong ethical thread running through the company and a desire to "give back" which it achieves through the MJF Charitable Foundation, which supports education, entrepreneurship and empowerment. Its very easy to be a bit cynical about initiatives like this by companies - however, you do get the sense that this is driven by a genuine intent to make the world a better place and put business to work improving the lives of everyday people. In a nutshell, you can drink a shed load of this tea, and feel pretty good about yourself too, knowing you're helping in a small way. Here's their website if you want to know more: https://www.dilmahtea.com/

|

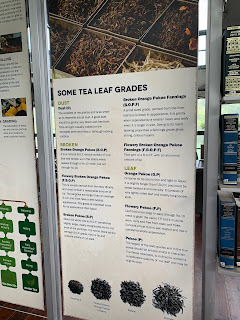

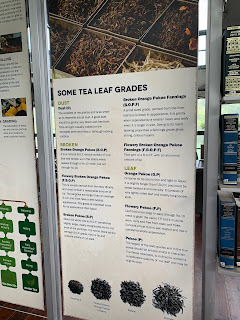

All the different tea grades, from dust to

orange pekoe to broken orange pekoe |

Anyway, back to the tour. Bernd was a lovely chap with a warm sense of humor and who had been involved in the tea business all his life. He started as a tea picker out in the fields, but then worked his way up, becoming a tea taster, a tea trader as well as a production supervisor. He was also telling us that he'd visited Chicago a couple of years earlier - he'd be invited to judge a culinary competition where the task was to pair food with various teas, similar to how food is paired with wine. So he was excited to hear we were from Chicago, so was sharing his experiences of the city with us.

The process of making tea is both very simple and devilishly complex. There is no chemical processing involved - in a nutshell, you follow only a few main steps. Here's the Wikipedia description of the full process:

Tea is cultivated in Sri Lanka using the ‘contour planting’ method, where tea bushes are planted in lines in coordination with the contours of the land, usually on slopes. For commercial manufacture the ‘flush’ or leaf growth on the side branches and stems of the bush are used. Generally two leaves and a bud, which have the flavour and aroma, are skilfully plucked, usually by women.

[34] Sri Lanka is one of the few countries where each tea leaf is picked by hand rather than by mechanization; if machinery were used, often a considerable number of coarse leaves and twigs could be mixed in, adding bulk but not flavor to the tea.

[34] With experience the women acquire the ability to pluck rapidly and set a daily target of around 15 to 20 kg (33 to 44 lb) of tea leaves to be weighed and then transported to the nearby tea factory. Tea plants in Sri Lanka require constant nurturing and attention. An important part of the process is taking care of the soils with the regular application of fertilizer. Younger plants are regularly cut back 10–15 cm (4–6 in) from the ground to encourage lateral growth and are pruned very frequently with a special knife.

The tea factories found on most tea estates in Sri Lanka are crucial to the final quality and value of manufactured tea. After plucking, the tea is very quickly taken to the muster sheds to be weighed and monitored under close supervision, and then the teas are brought to the factory.

[34] A tea factory in Sri Lanka is typically a multi-storied building and located on tea estates to minimize the costs and time between plucking and

tea processing. The tea leaves are taken to the upper floors of the factories where they are spread in troughs, a process known as withering, which removes excess weight in the leaf. Once withered, the tea leaves are rolled, twisted and parted, which serves as a

catalyst for the

enzymes in the leaves to react with the oxygen in the air, especially with the production of black tea.

|

| Tea roller machine |

The leaves are rolled on circular brass or wooden battened tables and are placed in a rotating open cylinder from above. After rolling is finished, the leaf particles are spread out on a table where they begin to ferment upon being exposed to heat. However, the preliminary heat is from the natural air temperature, so fermentation times fluctuate according to the

temperature and

humidity. Regulating the temperature, humidity and the duration of fermentation times requires a great deal of attention, and failure to follow the exact guidelines will make the flavor of the tea disappear.

[34] As oxidization occurs the colour of the leaf changes from a green to a bright coppery color. It is now that artificial heat comes into play as the fermented leaf is inserted into a firing chamber to prevent further chemical reactions from taking place. The tea leaves are fired to retain the flavour after the fermentation process is complete.

[34] Again the regulation of the temperature plays an important role in the final quality of the tea, and on completion the tea will become black and harder.

Grading (ordered by size in Sri Lanka) then takes place as the tea particles are sorted into different shapes and sizes by sifting them through meshes. No artificial preservatives are added at any stage of the manufacturing process and sub-standard tea which fails to initially comply with standards is rejected regardless of the quantity and value.

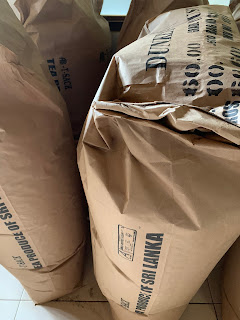

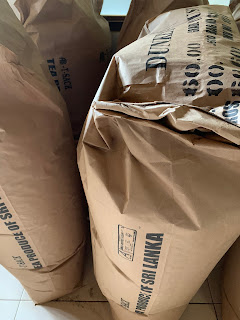

[34] Finally, the teas are weighed and packed into tea chests or paper sacks and then given a close inspection. The tea is then sent to the local auction and transported to the tea brokering companies.

[34] At the stage of exporting the Sri Lanka Tea Board will check and sample each shipment after the completion of packing to ensure that the finest quality tea is exported and then it is finally shipped in various forms of packing to many parts of the world.

[34]

|

| Tea naturally fermenting |

|

| Final processed tea all packaged up ready for shipping |

|

| Tea is sifted to sort it into different grades |

|

Tea samples are packed into these little boxes

and distributed across the world ahead of auction.

Same method has been used for 150 yrs |

|

| Millions of these little boxes are circulated daily |

|

| Each batch of tea is sampled and rated for taste, flavor etc |

|

| Tea pickers bringing their harvest in for weighing |

|

| Our chariot awaits to take us back across the lake |

So that's how tea is made. At least in Sri Lanka. Needless to say, I bought a fair amount to bring home (broken orange pekoe is my favorite) so i'll be well caffeinated for a while! (quick bit of triv for you - "orange" has nothing to do with the color in the descriptor - it actually refers to the old royal House of Orange (Dutch royal family, I think) who were noted tea drinkers so everyone wanted to style themselves after them).

Tomorrow, we have a lovely hike through the tea plantations and lunch at one of the other bungalows. For now, time to relax and enjoy the glorious views!

Anyway, enough of that.

Our first day was a pretty lazy day, with the only thing on the

itinerary the Tea Experience – a tour of the Dilmah tea factory, that’s nestled up in

the hills. Breakfast was served out on

the back verandah, overlooking the lake – despite the rain (again), the views

were still pretty breathtaking. From our

vantage point, you could see one of the other Tea Trails bungalow, Castlereagh,

across the lake. To get to it, you

walked down through the sloping grounds to the jetty, where a little putt-putt

boat was moored, ready to ferry us across the lake later that morning for our

tea tour. We enjoyed a very yummy

English breakfast (thanks, Baby Chef) and afterwards, the chef came out to run

through the menu for lunch and dinner that day.

All terribly civilized!!

Anyway, enough of that.

Our first day was a pretty lazy day, with the only thing on the

itinerary the Tea Experience – a tour of the Dilmah tea factory, that’s nestled up in

the hills. Breakfast was served out on

the back verandah, overlooking the lake – despite the rain (again), the views

were still pretty breathtaking. From our

vantage point, you could see one of the other Tea Trails bungalow, Castlereagh,

across the lake. To get to it, you

walked down through the sloping grounds to the jetty, where a little putt-putt

boat was moored, ready to ferry us across the lake later that morning for our

tea tour. We enjoyed a very yummy

English breakfast (thanks, Baby Chef) and afterwards, the chef came out to run

through the menu for lunch and dinner that day.

All terribly civilized!!

Tea is cultivated in Sri Lanka using the ‘contour planting’ method, where tea bushes are planted in lines in coordination with the contours of the land, usually on slopes. For commercial manufacture the ‘flush’ or leaf growth on the side branches and stems of the bush are used. Generally two leaves and a bud, which have the flavour and aroma, are skilfully plucked, usually by women.[34] Sri Lanka is one of the few countries where each tea leaf is picked by hand rather than by mechanization; if machinery were used, often a considerable number of coarse leaves and twigs could be mixed in, adding bulk but not flavor to the tea.[34] With experience the women acquire the ability to pluck rapidly and set a daily target of around 15 to 20 kg (33 to 44 lb) of tea leaves to be weighed and then transported to the nearby tea factory. Tea plants in Sri Lanka require constant nurturing and attention. An important part of the process is taking care of the soils with the regular application of fertilizer. Younger plants are regularly cut back 10–15 cm (4–6 in) from the ground to encourage lateral growth and are pruned very frequently with a special knife.

Tea is cultivated in Sri Lanka using the ‘contour planting’ method, where tea bushes are planted in lines in coordination with the contours of the land, usually on slopes. For commercial manufacture the ‘flush’ or leaf growth on the side branches and stems of the bush are used. Generally two leaves and a bud, which have the flavour and aroma, are skilfully plucked, usually by women.[34] Sri Lanka is one of the few countries where each tea leaf is picked by hand rather than by mechanization; if machinery were used, often a considerable number of coarse leaves and twigs could be mixed in, adding bulk but not flavor to the tea.[34] With experience the women acquire the ability to pluck rapidly and set a daily target of around 15 to 20 kg (33 to 44 lb) of tea leaves to be weighed and then transported to the nearby tea factory. Tea plants in Sri Lanka require constant nurturing and attention. An important part of the process is taking care of the soils with the regular application of fertilizer. Younger plants are regularly cut back 10–15 cm (4–6 in) from the ground to encourage lateral growth and are pruned very frequently with a special knife.

The leaves are rolled on circular brass or wooden battened tables and are placed in a rotating open cylinder from above. After rolling is finished, the leaf particles are spread out on a table where they begin to ferment upon being exposed to heat. However, the preliminary heat is from the natural air temperature, so fermentation times fluctuate according to the temperature and humidity. Regulating the temperature, humidity and the duration of fermentation times requires a great deal of attention, and failure to follow the exact guidelines will make the flavor of the tea disappear.[34] As oxidization occurs the colour of the leaf changes from a green to a bright coppery color. It is now that artificial heat comes into play as the fermented leaf is inserted into a firing chamber to prevent further chemical reactions from taking place. The tea leaves are fired to retain the flavour after the fermentation process is complete.[34] Again the regulation of the temperature plays an important role in the final quality of the tea, and on completion the tea will become black and harder.

The leaves are rolled on circular brass or wooden battened tables and are placed in a rotating open cylinder from above. After rolling is finished, the leaf particles are spread out on a table where they begin to ferment upon being exposed to heat. However, the preliminary heat is from the natural air temperature, so fermentation times fluctuate according to the temperature and humidity. Regulating the temperature, humidity and the duration of fermentation times requires a great deal of attention, and failure to follow the exact guidelines will make the flavor of the tea disappear.[34] As oxidization occurs the colour of the leaf changes from a green to a bright coppery color. It is now that artificial heat comes into play as the fermented leaf is inserted into a firing chamber to prevent further chemical reactions from taking place. The tea leaves are fired to retain the flavour after the fermentation process is complete.[34] Again the regulation of the temperature plays an important role in the final quality of the tea, and on completion the tea will become black and harder.  Grading (ordered by size in Sri Lanka) then takes place as the tea particles are sorted into different shapes and sizes by sifting them through meshes. No artificial preservatives are added at any stage of the manufacturing process and sub-standard tea which fails to initially comply with standards is rejected regardless of the quantity and value.[34] Finally, the teas are weighed and packed into tea chests or paper sacks and then given a close inspection. The tea is then sent to the local auction and transported to the tea brokering companies.[34] At the stage of exporting the Sri Lanka Tea Board will check and sample each shipment after the completion of packing to ensure that the finest quality tea is exported and then it is finally shipped in various forms of packing to many parts of the world.[34]

Grading (ordered by size in Sri Lanka) then takes place as the tea particles are sorted into different shapes and sizes by sifting them through meshes. No artificial preservatives are added at any stage of the manufacturing process and sub-standard tea which fails to initially comply with standards is rejected regardless of the quantity and value.[34] Finally, the teas are weighed and packed into tea chests or paper sacks and then given a close inspection. The tea is then sent to the local auction and transported to the tea brokering companies.[34] At the stage of exporting the Sri Lanka Tea Board will check and sample each shipment after the completion of packing to ensure that the finest quality tea is exported and then it is finally shipped in various forms of packing to many parts of the world.[34]

No comments:

Post a Comment